Electronic Ignition Systems

Electronic Ignitions are considered Custom Projects and are not available for purchase on line.

In order to successfully complete your request we will require more than your verbal description of the project.

As we are dealing with exact's and safety you MUST provide sketches, pictures, drawings, etc - anything other than your oral description. We reserve the right to refuse service if you do not provide our request for visual details.

Please begin by E-mailing your information to Ed@Moderustic.com

For those who need support - please send a detailed explanation of your issues accompanied with high resolution digital photos to Ed@Moderustic.com NOTE* Support is ONLY given to those who provide digital photos.

A made to order 72" by 42" fire table with a custom powder coat color.

Natural gas Hot Wire Ignition (HWI) system.

Lastly, a custom wind shield for his fire. The FireGlass used was Bronze Rust Copper Base Glass.

____________________________________________________________________________________

Click HERE or on the pictures of the Ritz Carlton Vortex' at Amelia Island Florida to how these were built. See the Videos!

Ritz Carlton Vortex Florida from Edgar Jaunzemis on Vimeo.

Ritz Carlton Vortex Page

_____________________________________________________________________________________

__________________________________________________________________________

CLICK HERE or on the pictures below to see how Knott's Berry Farm fire pit finished!

__________________________________________________________________________

We provided a total of 3 electronic ignition systems and Clear Base Glass for this great outdoor restaurant in Arlington Texas.

Besides the fire pit we also helped correct there other fire pit - check it out on our famous "How Not To Do it" page.

This project was from the Roxbury Hotel in NY. We worked with them in 2007 and then they contacted us again back in 2012 while working on redesigning one of their suites. They wanted a custom fire feature that entailed fire coming out from a Mayan head statue. See we went to work on figuring out how to make an electronic ignition system work in a cylinder shaped vessel???

We tried several different hole caps to see what kind of flame patterns we could achieve.

Once we were happy we finalized our modifications for the IPI system and installed it in the head statue.

Here are some renovations pictures of the room as it was being renovated.

And here is the custom fire feature completed and installed, ready to light with a flick of a switch.

The Roxbury, Contemporary Catskill Lodging

2258 County Highway 41

Roxbury, NY 12474

607.326.7200 607.326.3311 (fax)

The following electronic ignition system was designed for the Lavender Bistro in Palm Desert. They were constructing a 14' foot outdoor fire pit with three 66" inch stainless steel linear burners.

The gas manifolds required 3 valves to regulate the gas flow to the burners; all stainless steel construction.

Below in the pit, 1/4 Starfire Base Glass, Lillac Topper, Hyacinth Topper, Purple Topper, Fuchsia Topper, Pink Topper, and Violet Topper.

These are our modulated and controlled electronic ignition systems. The units are capable of 415,000 BTU's and come in a 13" x 13" x 4" water tight stainless steel box. The electronic ignition systems require 110 volts, come with a 60" maximum ignition lead and can be used on propane or natural gas. We also now offer 13" x 8" x 4" boxes!

Click here for the electronic ignition manual. This will require Word 2007 to open.

The units below are the Hot Wire Ignitions, 400,000 btu capability for natural gas or propane.

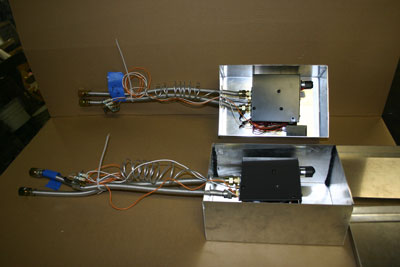

The two boxes below are our IPI battery operated electronic ignitions which are 100,000 BTU rated. The exterior boxes are built to protection the components from weather. These are typically installed under the glass in a fire pit our doors under the glass or in a sub panel just like our 110 volt electronic 415,000 BTU units.

On the left you can see the gas lines, one in and one out along with a 60" IPI lead (Intermittent Pilot Ignition). This allows the ignition system to be 60" away from the flames if required.

The

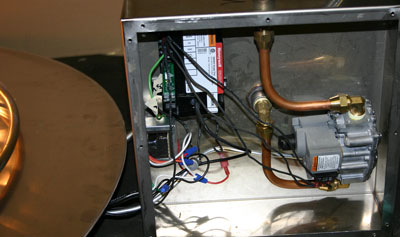

Electronic Ignition System below is a dual Ignition in one box. It was installed in a back to back set of fireplaces. The pictures below show the parts while being tested. Every system we build we test! We don't let any system go out unless it was tested several ways, especially propane!

This was an outdoor application which required a top to protect the electronics.

The burner below has a 300,000 BTU controller, 36" triple ring mounted on a 48" aluminum base plate for a fire pit in San Diego. These can be adapted for natural gas or propane with up to a 96" lead pilot light and ignite.

The next several pictures show you a flip top box design for a fire pit control panel. It is constructed from stainless steel or could be made from aluminum. The trimming valves are for adjusting the flame are inside along with an electronic key to activate the electronic ignition. These were made for an apartment complex and only the management had control of the electronic ignition. Here are the pictures. These two separate boxes were made to fit each specific fire pit.

The IPI used in the fireplace below is a battery operated. The fireplace below was done for Nick Cannon (http://www.NickCannon.com /) (now married to Mariah Carey) in Hollywood Hills California.

We installed a remote control inside of the fireplace on the left side as you will see. The remote control was an IPI (Intermittent Pilot Ignition) so the pilot light only goes on when you turn the fireplace on with the remote control.

We use a lava base filler and topper it with 1/8" Black Base Glass for a very fine layered look. The fireplace was coated with a high heat concrete mix to make it look wider and lower. A very contemporary look and it looks great.

We add the 1/4" Black Base Glass FireGlass to create a very simple but elegant fireplace. The remote went inside the fireplace on the left. You almost can't see it because of the dark glass color. There was initially a plan to build a housing cabinet, but the plumber forgot to show up! But everything turned out OK and everyone was happy.

The two pans below are stainless steel and are propane fueled with 415,000 BTU electronic ignitions each.

This propane pan was designed with a remote control unit that was concealed with a removal panel.

This keep the aesthetic of the custom pan by concealing the components.

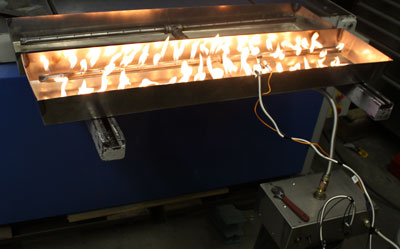

The twin ribbon burners below are 50" long each and powered be an electronic ignition. The will be installed in Santa Barbara California. They will be installed one in front of the other to create two walls of fire. These we mock up shots with very low pressure in the shop and when they get installed you will be able to see the potential of these burners.

The ignition system that was powering these burners is a 110 volt 415,000 BTU system. The control of the flame height can only be done manually as electronic control is not available as of yet for this unit.

Here are some pictures sent to us by our customer in Beverly Hills, California. We provided the FireGlass and a custom candle pan burner with

electronic ignition. We used a

Clear Base Glass for a simple modern look.

If you take the time to notice the nice texture of the glass. It's because we tumble it (patent pending, now PATENTED!) that's what also make us and our glass different from anyone else.

The fire pit below is in Newport Beach California at Newport Coast Development. We replaced a hot spark ignition which did not work, with our IPI (intermittent Pilot Ignition) electronic ignition system. The fire pit was 18" deep and 48" across. Looked pretty nasty when we got there.

We started to pour the lava with our electronic ignition being raised to the surface by the lava.

We built a double box to protect the equipment in the fire pit as well. The ring is now installed.

The electronics can be accessed if ever there was a failure of the equipment and you can access it from the surface. Before the equipment was 20 inches below the surface, not a very good idea! Now we poured the 144 lbs of Clear Base Glass over the lava.

We only did the fire pit, not the very impressive view!

This is what was installed:

We will show you from beginning to end:

As you have looked at all of our pictures we would like you to know we use

Crystals as our

Toppers and Toppings. We don't use "Recycled" glass, ever! We are actually the only company that produces

Crystals for fireplace and fire pits.

The electronic ignitions that were used in the Renaissance Hotel in Arizona were our MVKEI HC-5 units for natural gas. We used flame rod sensors on these torches.

13 of these were installed around the hotel. We use 12" stainless steel rings on the torches.

Burning wood and logs is just nasty and dirty! True story! Above you can see the soot that come out of the fireplace and and leaves your house smelling so carbon monoxide fresh! YUCK!

Add a bit of lime stone. A few pieces of copper.

Below you can see the sand bed and the ignition box we built. Below are the two vent we installed for the air mixers inside of the

ignition systems.

and here we are finished. Now isn't that much better little feller? Modern times call for modern measures! I guess that's why we are Moderustic!

The stainless steel pan burner below has a 24" stainless steel star burner installed and it is connected to our 110 volt electronic ignition. This is a propane burner.

We then covered it with our Starfire Base Glass to test for soot and as you can see, a clean burn.

The two fire tubs below were for the Anaheim Marriott in California. The two stainless steel surrounds were installed into the rock fire pit to conceal the electronic ignitions. They had placed logs on top.

These can be made in any size or shape.

The fire pit below is located in San Diego, Gable Point Loma. There were 2 electronic ignitions installed and a false bottom was installed. We filled the base with Clear Base Glass and 1/2" Clear Base Glass. The lines were installed from the back. Below are the electronic ignitions.

Framing/ metal studs were installed and two layers of durock was then installed to support the glass.

Finished!

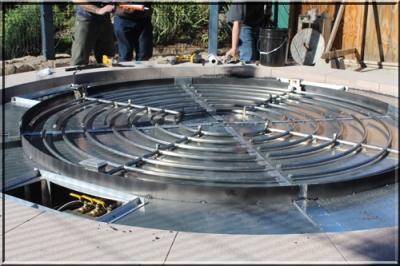

The fire pit below is in Marksville Louisiana and is at the Paragon Casino. The fire pit had an 18' fire ring installed in #304 stainless steel. The was done in and aluminum trough with 10 individual center feed burners. The gas line was a 1 1/2" and 5 lbs of pressure at 7" water column on natural gas. The ignition system is a Honeywell Infrared Flame Detection system. We will post more information on these larger fire features.

The big white ball is actually the Pearl of Louisiana.

Below is the fire ring in its trough surrounded by the water feature.

Below is one of the sections with the stainless steel burners. The complete feature is filled with water all around the fire ring.

The next two fire pits were at the same location, Newport Beach California. We installed an electronic ignition in each fire pit. These are spark to pilot ignition systems. Notice the 1/4 turn ball valve on top of the ignition box.

We then made a flip top box to access the valve to adjust the flame height. We used the old burners that were already in the fire pit previously.

We filled the fire pit up with the rock that was previously installed. Then we covered everything back up with their lava. The flip top box was also covered with lava. We just left it exposed so you could see how this was done. Both fire pits were electronically controlled by a Questron system. Simply by power on or power off. The flame can only be adjusted manually.

The next pan was installed in the Hampton's by Hampton Hearth, It is an 1/8" stainless steel pan with 400,000 btu electronic ignition. The next several pictures will show you how and what we did to complete the pan project.

We were hired to repair this fire pit at the Marriott in Torrance California. In the pictures you can see the plumbing sticking out of the pit, which we fixed. We cut a little bit of concrete and placed the valve in properly. This is an example of very poor attempt of installing a gas burner and valve.

Beyond the repair we upgraded the system to work with twin remote controls. The ignition was placed inside a metal box to protect it from the weather.

We covered the larger lava rock with our

crushed lava rock and then poured our 1 1/2"

Ford Blue Base Glass FireGlass over a pair of 44" stainless steel "H" burners. We always recommend using stainless steel burners and parts to avoid rusting.

The fire pit below has an electronic ignition and Clear Base Glass installed. This is next to the San Diego Stadium Downtown San Diego at the "Legends" Again this was installed by Cesar, one of our dealers in San Diego.

The round pan below is a propane pan with electronic ignition. This is a 36" aluminum pan with a 2" lip all around

GO TO PAGE 2